Overall, there are eight common gears that vary in design. Each gear is designed for specific scenarios and situations, depending on where it is going to fit into the build of the product. For an inside scoop on the different features and characteristics of gear designs for each type of gear, continue reading below.

In addition to the features and characteristics of the gear being discussed below, each explanation will also give insight into the different applications that they are used for. Hopefully, this information will help you identify what gear you need and when, depending on the project or product you are working on.

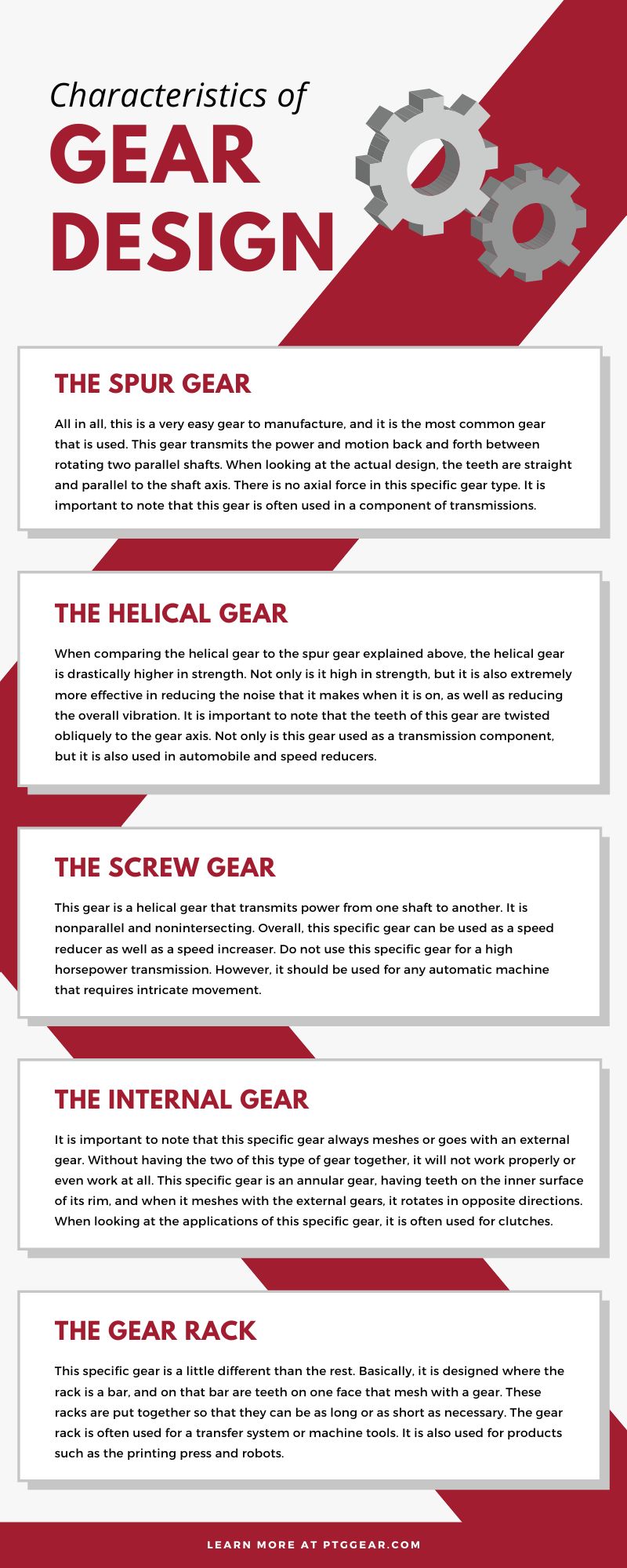

The Spur Gear

All in all, this is a very easy gear to manufacture, and it is the most common gear that is used. This gear transmits the power and motion back and forth between rotating two parallel shafts. When looking at the actual design, the teeth are straight and parallel to the shaft axis. There is no axial force in this specific gear type. It is important to note that this gear is often used in a component of transmissions.

The Helical Gear

When comparing the helical gear to the spur gear explained above, the helical gear is drastically higher in strength. Not only is it high in strength, but it is also extremely more effective in reducing the noise that it makes when it is on, as well as reducing the overall vibration. It is important to note that the teeth of this gear are twisted obliquely to the gear axis. Not only is this gear used as a transmission component, but it is also used in automobile and speed reducers.

The Screw Gear

This gear is a helical gear that transmits power from one shaft to another. It is nonparallel and nonintersecting. Overall, this specific gear can be used as a speed reducer as well as a speed increaser. Do not use this specific gear for a high horsepower transmission. However, it should be used for any automatic machine that requires intricate movement.

The Internal Gear

It is important to note that this specific gear always meshes or goes with an external gear. Without having the two of this type of gear together, it will not work properly or even work at all. This specific gear is an annular gear, having teeth on the inner surface of its rim, and when it meshes with the external gears, it rotates in opposite directions. When looking at the applications of this specific gear, it is often used for clutches.

The Gear Rack

This specific gear is a little different than the rest. Basically, it is designed where the rack is a bar, and on that bar are teeth on one face that mesh with a gear. These racks are put together so that they can be as long or as short as necessary. The gear rack is often used for a transfer system or machine tools. It is also used for products such as the printing press and robots.

The Bevel Gear

There are two different types of bevel gears. The first one is the straight bevel gear, while the second is referred to as the spiral bevel gear. For both of the designs, teeth are cut along the pitch cone. Here are some characteristics of both types of bevel gear:

- Straight Bevel Gear— This specific gear is easy to manufacture and is used in a multitude of different applications. The straight bevel gear has straight teeth and comes together at the intersection of the shaft axes. Machine tools and printing presses are two of the most common applications for this specific gear.

- Spiral Bevel Gear— It is important to note that this gear is much more complex and difficult to manufacture than the straight bevel gear. This gear has curved, oblique teeth. It is designed this way because it allows for gradual engagement and a large contact surface, especially when compared to the straight bevel gear. Overall, the way that this gear is designed lends it higher strength and durability than the straight bevel gear. It also allows for a higher reduction ratio and a better efficiency of transmission. This gear is used for automobiles, tractors, vehicles, and is suitable for heavy load drives, as well as in high-speed scenarios.

The Miter Gear

Note that this is another type of bevel gear. This is a special and unique bevel gear. It is designed in a way that the shaft intersects at a 90-degree angle and the gear ratio is 1:1. This gear is used to change the direction of the gear shaft, without allowing the gear to change in speed. While this is not the most commonly used bevel gear, it does get used for specific and unique projects and products.

The Worm Gear

The Worm Gear is a gear that is used to transmit motion between two shafts that are 90-degrees from each other on the same plane. This specific design allows for large reduction ratios, as well as for being quiet and smooth throughout while it is running. Common applications for this specific gear design include speed reducers, machine tools, indexing devices, chain blocks, portable generators, and more.

All these gears explained above have different components and aspects that make them different from one another. While many of them have similarities, it is their differences that allow for them to be perfect for specific jobs within several different types of products. Hopefully, the information shared above regarding the characteristics of gear design helped you develop a solid or at least foundational understanding of the different types of gears.

If by chance you are in search of a custom gear manufacturer that can not only help you find exactly what type of gear you need, but that can also help you create that gear, then you have come to the right place. Here at Blaz-Man Gear Inc.—Power Transmission group, we can help create a gear for any purpose or project. All you have to do is call or visit our website today to speak with our professionals regarding all of our custom services.