For an in-depth explanation of the different types of gears, and their applications, click here. This article gives a solid start on all things gears.

Gears are machine elements that transmit rotation and forces. There are several different types of gears and uses. Understanding the variations within the different types is important when choosing what one to use for specific applications. It’s also important to understand what separates the different types of gears and what exactly makes them different. To get a better and more in-depth understanding of all of the gears and their uses, continue reading the material below. Please keep in mind that all of the different types of gears are not covered throughout this content, but the majority of the most common ones have information present.

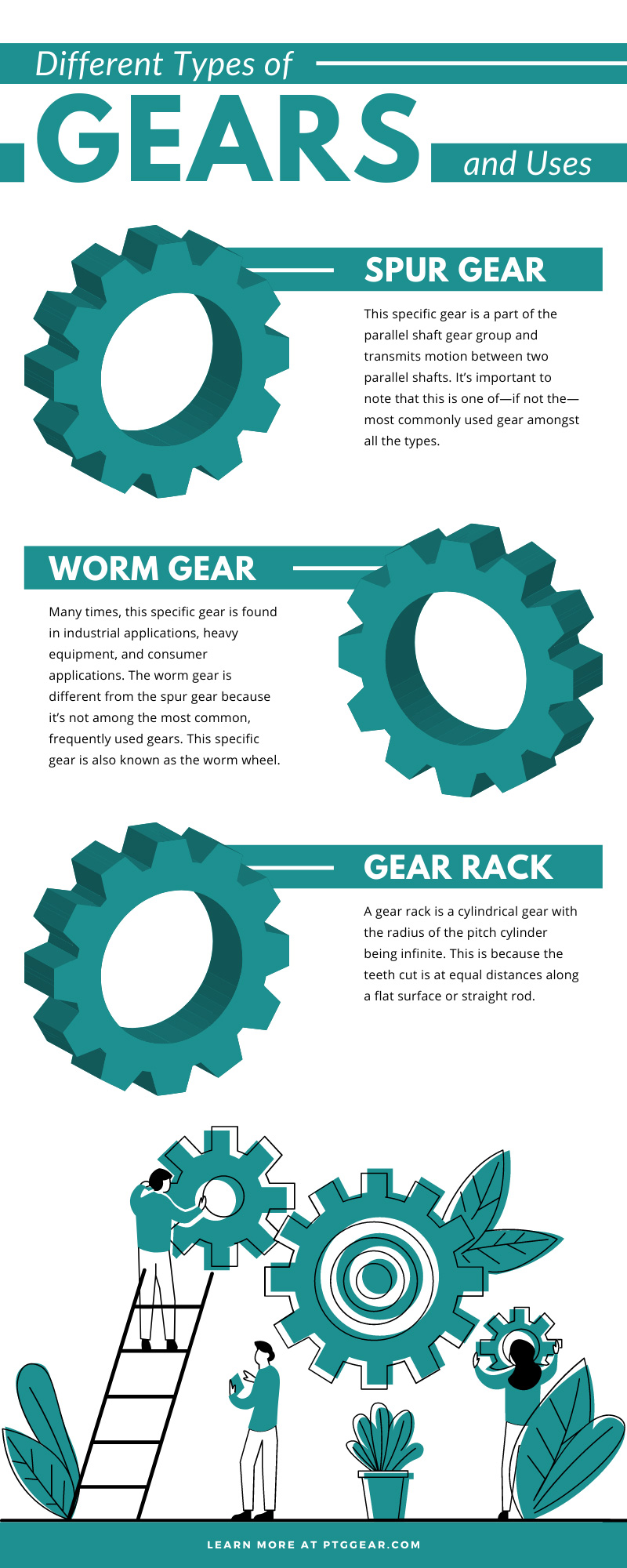

Spur Gear

This specific gear is a part of the parallel shaft gear group and transmits motion between two parallel shafts. It’s important to note that this is one of—if not the—most commonly used gear amongst all the types. Not only can it achieve high accuracy when in use, but as an added bonus the gear itself is easy to produce. Unfortunately, what stops individuals from using this specific gear is the noise it produces.

The spur gear is best for any application that needs speed to reduce or torque multiplication. Some examples of common uses of this specific gear include washing machines and blenders. They are also often used in crushing machines and ball mills.

Worm Gear

Many times, this specific gear is found in industrial applications, heavy equipment, and consumer applications. The worm gear is different from the spur gear because it’s not among the most common, frequently used gears. This specific gear is also known as the worm wheel. The worm gear allows for high reduction ratios and corresponds well with high torque multiplications. At times it’s used for speed reducers in low-to-medium speed applications as well. Another benefit to this gear is that they’re typically self-locking, which make them perfect for hoisting and lifting uses.

Gear Rack

A gear rack is a cylindrical gear with the radius of the pitch cylinder being infinite. This is because the teeth cut is at equal distances along a flat surface or straight rod. The flat surface or straight rod is known as the gear rack. This specific gear’s main function is to convert rotating movement into linear motion. As you can infer, this gear is used in any wheel that needs to provide direction.

Bevel Gear

Bevel gears are different from the other gears in a variety of ways, starting with the fact that it’s in the shape of a cone. That is not the case for many of the other gears. The way this specific gear works is that it transmits force between two shafts intersected at one specific point. The teeth of this gear are along the cone.

The applications of bevel gears are very diverse. This specific gear is often the main element in cars to transmit speed, power, and rotation. A few other common uses of bevel gears include the printing press, marine applications, steel plants, and railway track inspections.

Internal and External Gears

The external gear is on the outer surface of the cylinder or cone, while the internal gear is on the inner surface of the same shape. Their main use is for planetary gear drives and gear-type shaft couplings. The number of teeth from internal to eternal gears differentiate. The internal and external gears mesh and work together in opposite directions. Many times, these gears are only used in planetary gearboxes, however, they can be applied in a variety of other situations.

Not only do these gears give off low vibration, but they also have a high-speed reduction ratio. In addition, they’re also low in cost, which is beneficial.

Helical Gear

The helical gear is similar to the spur gear in many ways. However, they have a much better tooth meshing, are much quieter, and can transmit higher loads. Their teeth are also different from spur gears because of they’re on an angle rather than straight. With the teeth like this, they aren’t parallel, but on an incline.

One might pick the helical gear over spur gears in situations where the load noise of spur gears isn’t welcome. These gears are specifically common features in transmissions. In addition to transmissions, the helical gear is also the main component in elevators, conveyors, and compressors.

Spiral Bevel Gear

These gears are bevel gears; however, they have curved tooth lines. The spiral bevel gear might even be superior to the straight bevel gear in a few ways. Not only are they more efficient, but they are strong and have less noise and vibration overall. The negative aspect of the spiral bevel gear is that it isn’t easy to produce. Any application that requires high speed and high torque power can use the spiral bevel gear.

All of these gears differ in use and design. Knowing the strengths and weaknesses of each one will help you determine which one is the best for the operation. After taking a look above at the different types of gears and uses, hopefully you now have a solid foundation going forward of the different gears in a general overview. It’s important to note, however, that not all of the different gear types were mentioned above; you can investigate others.

If you are looking for more information regarding gears or are looking for a company that creates custom-made gears, check our website out! Here at Blaz-Man Gear Inc. – Power Transmission Group, we can help customize any gearbox you could need. Reach out to our professionals today to start creating the high-quality gears that you need.